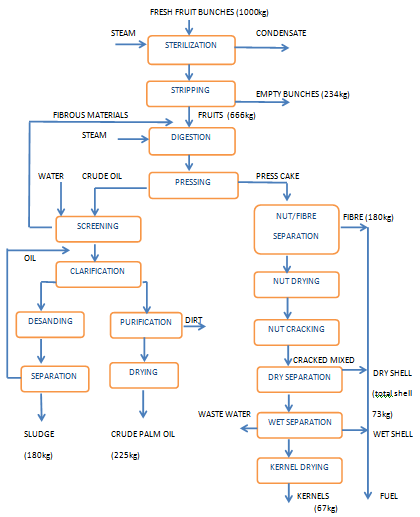

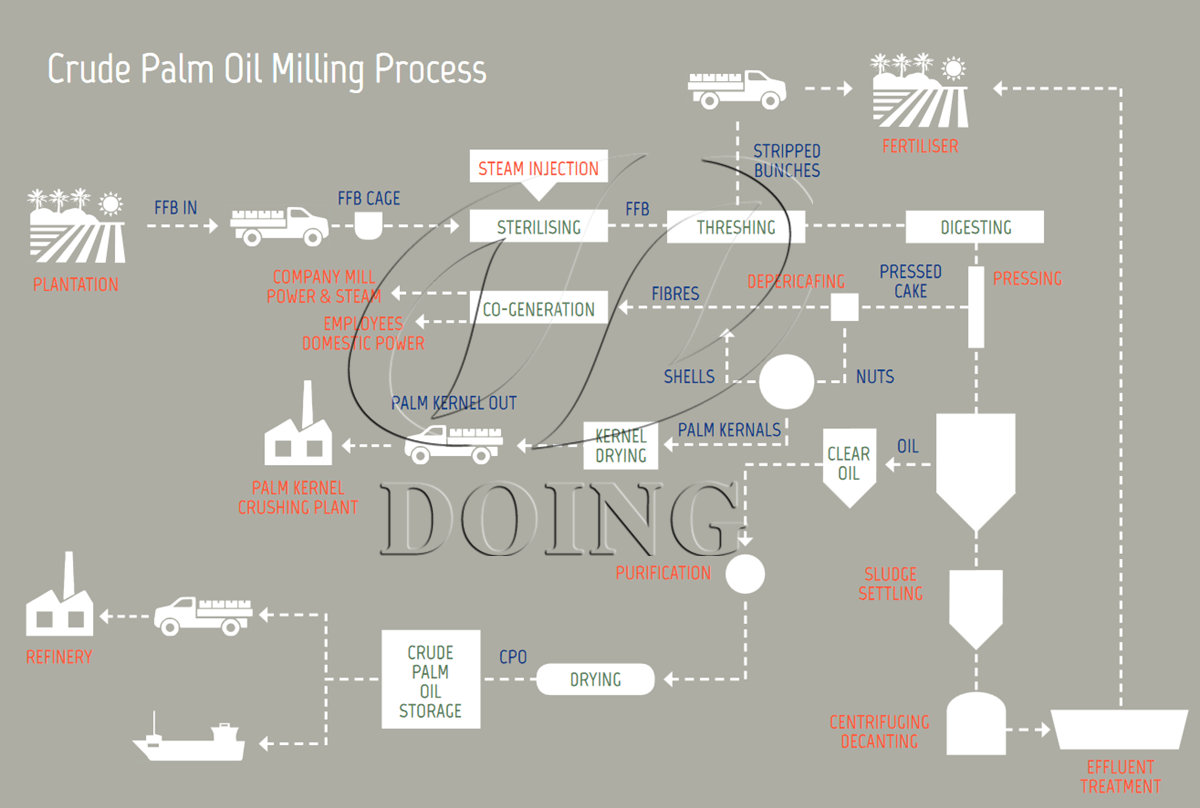

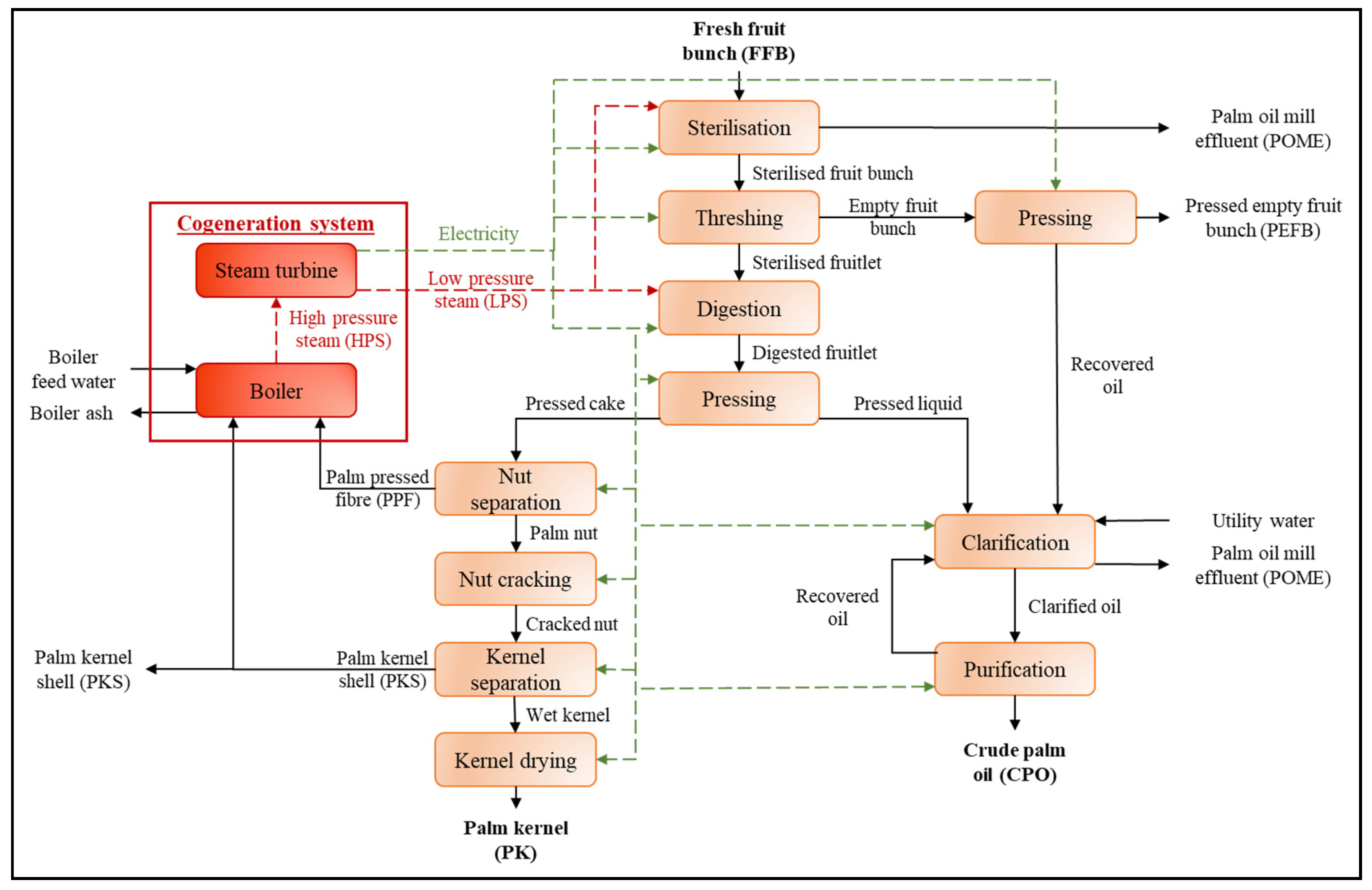

The oil winning process in summary involves the reception of fresh fruit bunches from the plantations sterilizing and threshing of the bunches to free the palm fruit mashing the fruit and pressing out the crude palm oil. Edible oil increases.

Highly Efficient Palm Oil Milling Process For Palm Oil Mill

The first step is sterilization boiling.

. However the increasing of palm production oil is also means increasing of water consumption. PDF On Apr 8 2019 Azam Akhbari and others published A study of palm oil mill processing and environmental assessment of palm oil mill effluent treatment. 1 50 millon tons of biomass has the potential of 14 trillion cubic meters of biogas or 337 MW of electrical power generation.

The pressed and de-sanded palm oil in this process is sent directly to the topd 3-phase decanter. If the palm oil mill has a demand or a market for biogas energy the POME sterilizer condensate and decanter biomass can be treated in a biogas plant. 15 Full PDFs related to this paper.

Palm oil mill process. Vol1 - OIL PALM MILL SYSTEMS PROCESS Vol3 - OIL PALM MILL MAINTENANCE MANUAL Noel Wambeck June 1999. FATTY ACID COMPOSITION OF PALM OIL AND FRACTIONS Palm Oil Palm Ole ne Palm Stearine 20 Fatty Acid C14o C16o C18o C181 C182 C183 Iodine Value Melting Pt.

PROCESS FLOWCHART OF PALM OIL MILL PROCESSING 1Bunch Reception. 314 Digestion of the fruit. 10 Degumming Bleaching Deacidification and deodorization Palm Fatty Acid Distillate REFINING PROCESS RBD Palm Oil CRUDE PALM OIL 180 - 260oC oC under vacuum Filtration Bleached Palm Oil 80oC - 90oC 90oC - 120oC FRACTIONATION PROCESS Fractionation Process physical process.

D Palm Oil Mill Schematic Process Flow E Matrix oil palm mill process. Intro to Palm Oil Processing. The entire palm oil mill process involves the reception of fresh fruit bunches from the plantations sterilizing and threshing of the bunches to free the palm fruit mashing the fruit and pressing out the crude palm oil.

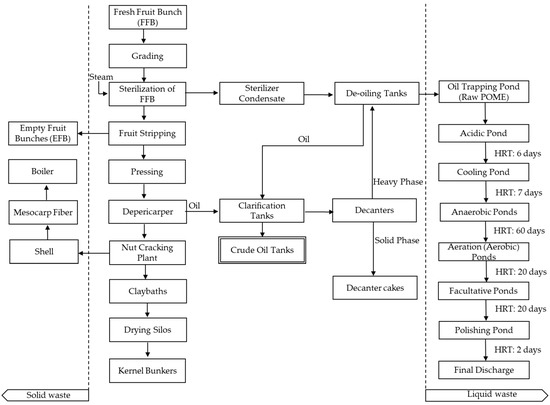

To produce one ton of palm oil about 5 tons of water required and most of the water will end up as waste water or Palm Oil Mill Effluent POME 1. In palm oil mills more than 90 of GHGs were emitted from POME. The upstream refers to the nursery plantation and milling process while the downstream refers to the crusher refineries and other final products Hai 2002.

The crude oil is further treated to purify and dry it. POME is a colorless liquid remains dark brown but. Establishing biogas plants to process Palm Oil Mill Effluent Introduction Greenhouse Gas GHG reduction and energy cost savings are two issues that are becoming increasingly important to businesses in a wide variety of sectors including the oil palm industry.

As indicated in Appendix 1 the proposed has palm oil mill y capacitfor milling 00 kg5 FFBhr and 5000kg of FFBday. Oil Clarifier Palm Oil Mill Effluent POME Palm Kernel. 100 1 100 found this document useful 1 vote 924 views 20 pages.

BULK STORAGE TANK Purified Crude Palm Oil is pumped into the Bulk Storage Tank. But an average milling rate of 2500kg. Palm oil mill residues such as oil palm fronds oil palm trunks palm oil mill effluent POME mesocarp fibres palm kernel shells and empty fruit bunches have emerging potential to be converted into value-added products.

2Sterilizatio n Empty EB fiber Bunch 4EB Compost for 3Threshing Pressing plantations Nut 10Kernal Station 8Sludge 5Digestion Oil EB Oil Press Recover 11Boiler Fiber 6Pressing y Turbine. Year decades with a yearly production of more than 13 million tons of crude palm oil and plantations covering 11 of the Malaysian land area. Palm oil processing technology pdf involves extracting palm oil from palm fruitPalm oil is processed in the African countries in 70 to 80 by traditional methodThe traditional palm oil extraction method is inefficiency and waste is serious.

Palm Olein 10 398 425 112 216 88 C14O mysterine acid C16O palmitic acid C18O stearic acid C18I oleic acid. OBJECTIVE To separate moisture from oil. Oc Could Point oc 60 Palm Oil 11 45 392 101 Std.

02 Increasing PO Yields by Measuring REpdf. Palm Oil Mill Process. The main advantage is.

Dark Red Rich in Micronutrient. Palm oil has been expanding rapidly since the late 1960s. VACUUM DRYER The oil is dried through vacuum dryer.

The crude oil is further treated to purify and dry it for storage and export. Palm oil mill process flow diagram click here. Sterilization is the first step of the palm oil process and it is done to prevent the rapid formation of free fatty acids during the pulping process and to remove any attached.

Revised 3nd March 2001. Solid 9496 water. Than 80 of palm oil is exported.

For this kind of POME with high dry matter. However the production of such amounts of crude palm oil result in even larger amounts of palm oil mill effluent POME estimated at nearly three times the quantity of crude palm oil Wu 2009. The palm oil milling process is summarized in Table 1 and illustrated further in Appendix 1.

Hassan et al 2004. The boiled fruits are conveyed to the digester. The digester commonly used consists of a steam-heated cylindrical vessel fitted with a central rotating shaft carrying a.

Fitosterol Need to be refined Refining Process. A short summary of this paper. Digestion is the process of releasing the palm oil in the fruit through the rupture or breaking down of the oil-bearing cells.

OIL PURIFICATION Moisture and dirt are separated by the oil purifier OBJECTIVE Oil purification from moisture and dirt. About 90 percent of palm oil exports go to markets in indus-trialized countries but exports to new markets in developing countries have shown the most rapid growth. Save Save Palm Oil Mill Process For Later.

In palm oil mill production line has become the most important subject to study as it relates to the efficient and effective in producing the Crude Palm Oil CPO and Palm Kernel PK. Slide 34 Wider Implications Item Examples Health hazard and safety aspects Opportunity to improve process safety Registration Evaluation Authorisation and Restriction of Chemical substances EU Sustainability aspects. From 1 ton crude palm oil 1100 kg CO 2eq GHGs are generated which can be.

The POME is generated mainly from the extraction of the Palm Oil the washing process and the cleaning of the mill. In line with the increasing trend of output world trade in palm oil more than doubled between 1969 and 1979. It is anticipated that the palm oil residues generated from the production process will also increase.

50 SPECIFICATION FOR MACHINERY 60 MECHANICAL ELECTRICAL DRAWINGS The complete Oil Palm Process Synopsis set includes the following.

Pdf Quality Control System Of Crude Palm Oil On Palm Oil Processing Industry Case Study Bah Jambi Palm Oil Mill Ptpn Iv Medan North Sumatra Muhammad Semantic Scholar

Palm Oil Production Process Pdf Company News

Flow Chart For Palm Oil Milling Download Scientific Diagram

A Schematic Process Flow Of Palm Oil Milling Process Download Scientific Diagram

Palm Oil Refinery Plant Manufacturing Vegetable Oil Products

Pdf A Review Of Palm Oil Mill Effluent Pome Water Treatment Semantic Scholar

Palm Oil Mill Process Manufacturers Palm Oil Mill Process Suppliers Exporters Sale Design Prices Cost Of Offer Palm Oil Process Flow Diagram Crude

Palm Oil Refinery Process Pdf Industry News

A Schematic Process Flow Of Palm Oil Milling Process Download Scientific Diagram

Pdf A Review Of Palm Oil Mill Effluent Pome Water Treatment Semantic Scholar

Pdf Palm Oil Mill Effluent Treatment Process Evaluation And Fate Of Priority Components In An Open And Closed Digestion System Semantic Scholar

Pdf Biological Treatment Of Palm Oil Mill Effluent Pome Using An Up Flow Anaerobic Sludge Fixed Film Uasff Bioreactor Semantic Scholar

Most Asked Questions About Palm Oil Refinery Plant Faq

Pdf Toward Cleaner Production Of Palm Oil Mills Part 2 Minimization Of Water Consumption And Process Optimization Semantic Scholar

Processes Free Full Text Palm Oil Mill Effluent Treatment Processes A Review Html

Processes Free Full Text Hybrid Approach For Optimisation And Analysis Of Palm Oil Mill Html

Membrane Based Zero Sludge Palm Oil Mill Plant